Why use a ball valve versus a globe valve?

There are many different types of valves available for different applications. With so much choice it can be difficult to decide which valve is most suitable for your application. In this article, BM Engineering Supplies explores the merits of ball valves versus globe valves.

What is the main difference between ball and globe valves?

The main difference between ball and globe valves is the way they close. Ball valves have a stem and ball, which turns horizontally, and are commonly referred to as “rotational” valves. Whereas, globe valves have a stem and plug, which strokes linearly, and gives them their other name of “stroke” valves. Ball valves are best suited to applications requiring on/off control without pressure drop. While globe valves excel at regulating flow.

How does a ball valve work?

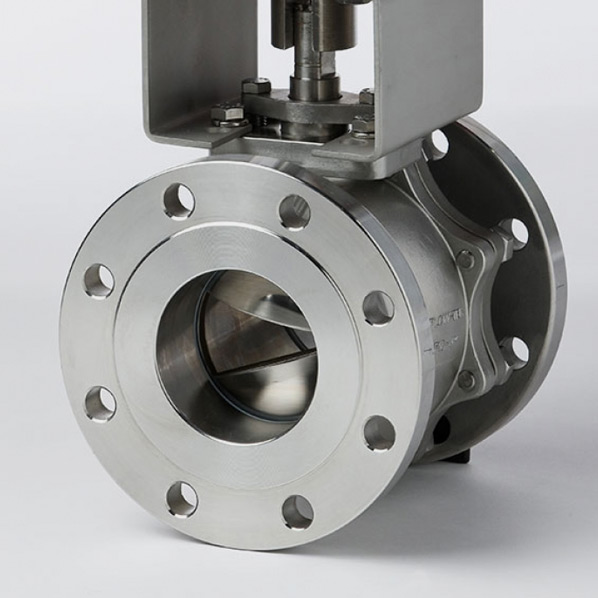

Ball valves are designed with a ball inside the valve. A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball (called a “floating ball”) to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status.

How does a globe valve work?

Globe valves were for many years the industry standard in control valves. They are named for their spherical body shape, with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug (or disc) can be screwed in to close the valve. Typically, automated globe valves use smooth stems rather than threaded and are opened and closed by an actuator assembly.

Which is better: a ball valve or globe valve?

Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff applications, where they are often preferred to gates and globe valves. On the flip side, ball valves do lack the fine control in throttling applications offered by globe valves.

BM Engineering Supplies stocks ball and globe valves

BME stock a wide range of ball valves, from quarter-inch to six-inch at our works in Bishopbriggs. From general purpose two-piece ball valves, v-ball control valves, hygienic valves, to heavy duty ball valves for steam; we have a variety of sizes, end connections and materials to suit many applications. We also stock globe valves up to six-inch in size, and can supply many size and material variants on a next-day basis.

Speak to one of BME’s knowledgeable advisers about your ball valve requirements today by calling 0141 762 0657 or email sales@bmengineering.co.uk. For more information please visit www.bmengineering.co.uk.test.