How do air compressor solenoid valves work?

Compressed air is a valuable commodity in countless industrial environments to power a huge array of tools and automated processes. Wherever compressed air are controlled, solenoid valves are used for the purpose. But how does an air compressor solenoid valve function, and what are the benefits of using one? BM Engineering explains everything you need to know about air compressor solenoid valves right here.

How do people use solenoid valves in air compressors?

Solenoid valves are electrically operated valves that control a wide range of fluids, including compressed air. An air compressor solenoid valve functions in several different ways. Household air conditioners, air conditioning systems, and automobile air conditioners all use it. It takes in filtered air, sends it to the refrigerator, and keeps it pressurised inside the air receiver tank.

The cut-off switch stops the motor when the tank reaches the required pressure. It de-energizes the valve to exhaust pressurized air and prevent damage to the compressor.

Different air compressor solenoid valve functions

Now that we’ve covered how an air compressor solenoid valve functions, let’s explore additional applications of solenoid valves in compressed air systems.

Intake control

Solenoid valves are often used to manage the intake control or the inlet valve in screw compressors. Available as either de-energised opening or de-energised closing versions, these types of valves deliver higher energy efficiency, gentle start-up and a lower pressure fluctuation range. Thereby prolonging compressor service life. Proportional valves provide particularly accurate load and energy consumption in mobile compressors.

Pressure maintenance

Pressure maintenance valves maintain stable pressure in the compressor and the compressed air preparation unit. A pressure maintenance valve effectively interfaces the compressed air system and the network. Its job is to ensure a safe start-up at all times. In addition, the pressure-retaining valve protects the compressor and other air treatment components if the network draw-off is low.

Control of the process valves: which solenoids can be utilised from our stock?

Pneumatic Solenoids

Condensate drainage

Contaminated condensate is a natural by-product of the air compression process. You need to drain and properly dispose of this liquid to prevent damage to the compressed air system. You can use a drain valve to carry out this task whenever the compressor is turned on and at set operating intervals. For optimal results, it’s best to connect the drain valve to a condensate treatment unit using a pipeline.

Purge air and change-over

The membrane dryer removes moisture from compressed air with the help of purge air from a pilot valve as needed. Change-over valves enable pressure surge-free change-overs in adsorption dryers and nitrogen or oxygen generators.

Accessories: Types 2516, 2518

Solution with process valves & valve islands: Types, 8640, 6519

Upstream pressure shut-off

Inlet valves are routinely placed before a booster compressor to control the air supply during operation. These air compressor solenoid valves function so that when the inlet pressure drops too low, they close automatically. This helps the booster compressor to draw in treated and pre-compressed air from an existing network or another low-pressure compressor and increase the pressure.

Pneumatic Atex Solenoids

When choosing a solenoid valve

– Choose a coil based on operating voltage (AC-DC) and provide appropriate protection and insulation.

– Consider minimum and maximum pressure values for the system.

– Take into account the fluid quality and temperature for valve selection.

– Ensure proper alignment of the fluid direction and arrow mark during installation.

– Install a check valve after the solenoid valve to prevent fluid backflow at reverse pressures.

– Keep the attached line free of impurities.

Air compressor solenoid valves at BM Engineering

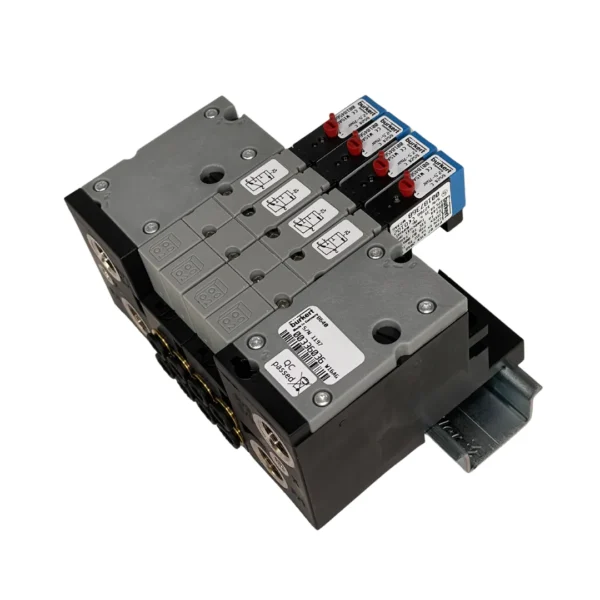

BM Engineering supplies a huge range of solenoid valves from industry-leading manufacturer, Bürkert and Max Air. Their selection of 3/2-way pneumatic solenoid valves, featuring three ports and two states, is popular for controlling a wide range of pneumatic equipment. Pneumatic solenoid valves are perfect for compressed air applications, providing a reliable and cost-effective solution.

Bürkert have a range of valves that are suitable for different applications. Their high-performance valves can deliver high flow rates with minimal power consumption, either individually or in blocks. For example the Bürkert Type 6013 that can purge air as required and ensure energy-efficient operation of the membrane dryer.

For more information about pneumatic solenoid valves or to discuss your application requirements in more detail, please contact our sales team on 0141 762 0657 or email sales@bmengineering.co.uk.