How Does A Mash Tun Work: A Guide To The Brewing Process

Crafting the perfect beer or whisky is an art form, a science and a good old-fashioned tradition. At the heart of this process, you’ll find the mash tun., If you are interested in the industrial brewing process, whether that be for beer or the first stages of the whisky process, you need an answer to the question: “How does a mash tun work?”. Let’s take a look into the intricacies of this crucial piece of brewing equipment.

What is a Mash Tun?

Mash tuns are brewing vessels used to turn the starch present in grains into sugar to be used for the fermentation process, typically when brewing beers and ales. Often constructed from stainless steel or insulated plastic, the vessel is specifically designed to accommodate the ‘mashing’ process. It needs to keep a stable temperature, usually between 60-70°C (140-158°F), to ensure optimal enzymatic conversion.

What Does a Mash Tun Do?

Basically, mash tuns act as a large cooking pot, designed to stew the malted barley (and other grains if used), creating a sweet liquid known as ‘wort’. The grains are soaked in hot water within the mash tun, initiating a process where enzymes break down the grain’s starches into simpler sugars. These sugars become the vital energy source for the yeast during the fermentation phase, which eventually provides a beer with its alcohol content.

The Inner Workings of a Mash Tun

A mash tun is more than just a container; it’s an efficient system designed for optimal brewing. It incorporates a ‘false bottom’ or a manifold, which is a slotted, perforated plate sitting above the actual bottom. This piece separates the liquid wort from the spent grain during the ‘lautering’ process, a method of filtering and sparging (rinsing) the grain bed.

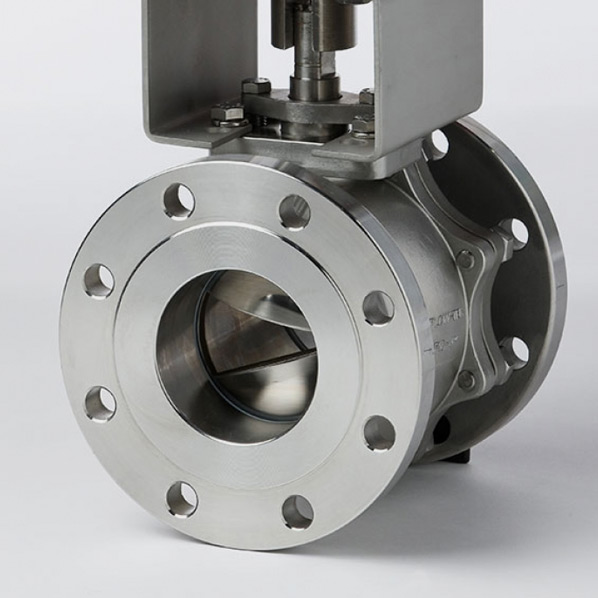

Then there’s the spigot or ball valve, which transfers the wort from the mash tun into the brew kettle. Some mash tuns also have a thermometer and a recirculation system for maintaining an even temperature throughout the mashing process. For added precision and control over the transfer process, the Orbinox EX Pneumatically Actuated Knife Gate Valve is the perfect solution for brewers, especially if brewing at scale.

All of these elements, working together, transform humble grains into the beginnings of an outstanding beer. It is not just the quality of the ingredients that influences a beer, the quality of the brewing equipment impacts taste, clarity, and aroma too.

The Mashing Process – From Grain to Wort

Now that we’ve broken down the parts, we can piece together the mashing process. It begins by heating water in the mash tun, known as ‘strike water’, to a temperature higher than the desired mash temperature (to account for the temperature drop when grains are added).

Then the milled grains are added and thoroughly stirred to ensure an even mix; this is your ‘mash’. Over a period of usually 60-90 minutes, the enzymes in the malted barley activate, breaking down the complex starches into fermentable sugars. During this time, the temperature is crucial. Too high can denature the enzymes, and too low can slow the process.

Following the mash, the wort needs to be separated from the spent grain. This is achieved by lautering – gradually drawing off the liquid, and recirculating it over the grain bed to set a natural filter, which clarifies the wort before it’s transferred to the brew kettle.

Cleanliness is Next to Godliness – Caring for Your Mash Tun

To ensure consistent and tasty results, maintaining the cleanliness of your mash tun is vital. After each brew, remove the spent grains, and thoroughly clean all parts, especially the false bottom, ball valves and thermometer. Neglecting this crucial step can lead to a build-up of residue, potentially imparting off-flavours in subsequent brews, and creating a haven for bacteria.

Remember to occasionally deep-clean your tun to maintain its peak performance, using suitable non-caustic cleaners and taking care to thoroughly rinse afterwards. Treat your mash tun well, and it will reward you with many successful brews. Keeping a stock of spare parts and accessories can help you maintain your mash tun, and keep brewing without having to interrupt a brew or wait for replacement parts.

The mash tun plays an integral role in the brewing and distilling process. From its initial action of steeping the grains to its efficient separation of wort from spent grain, it sets the stage for all the magic that makes our beloved beers, whiskies and other distilled alcohols. Next time you enjoy a tipple, take a moment to appreciate the mash tun, the vessel that made it all possible. Cheers to that!