What is a segmented ball valve?

In many industrial operations, precision in controlling the flow of fluids and gases is key to efficiency and product quality. Segmented ball valves are renowned for their exceptional ability to provide precise and granular control over a variety of critical industrial processes. These valves, characterised by a segment of a ball, rather than a full ball in a traditional ball valve, offer an unparalleled combination of precise range of movement, control, and shut-off capabilities.

The design ensures a seamless and precise regulation of flow, making them an ideal choice for industries where such precision is paramount. The distillery industry, for example, with its rigorous standards for purity, consistency, and consumer safety, relies heavily on the functionality of segmented ball valves. The ability to meticulously manage the flow and pressure of liquids directly impacts the quality of the distilled spirits, highlighting the importance of selecting the right valve for the task. But what is a segmented ball valve? Why are they so revered in so many industries? And, how can they help you?

What is a Segmented Ball Valve?

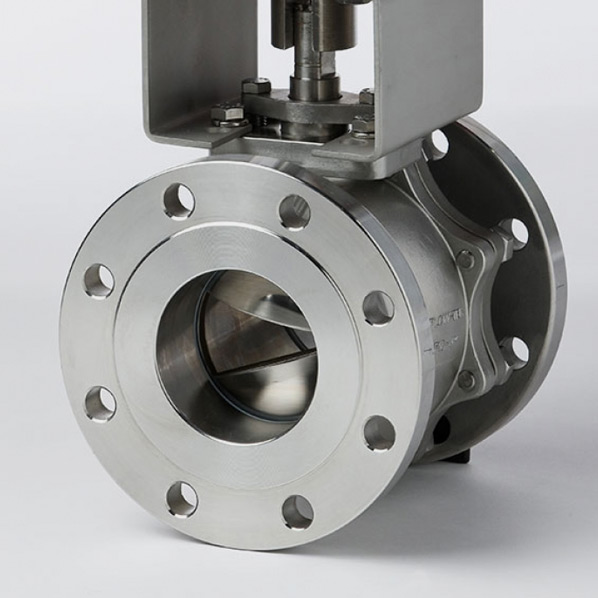

Segmented ball valves are a sophisticated variation of traditional ball valves that are engineered to offer superior control over fluid dynamics in industrial settings. These valves are distinguished by their unique ball design, which plays a critical role in their operation. This design allows for the precise regulation of flow rates, making them highly suitable for applications where exact flow control is crucial, such as in distilleries. The segmented ball allows the valve to handle a variety of flow conditions, from linear to equal percentage flow characteristics, providing versatility across a wide range of applications.

Any industrial operations that require the flow of fluids and gases to be precisely regulated can benefit greatly from the use of segmented ball valves, especially in industries where the accuracy of flow control can directly influence the quality of the end product. This is one of the reasons they are so widely used in the distillery industry, where one minor change in the flow of a fluid can affect taste, quality, and consumer satisfaction. The ability to finely tune the flow makes these valves invaluable in processes that demand precision. Whether your industry involves the handling of liquids, gases, or slurries, the segmented ball valve’s design can cater to a broad spectrum of control needs, improving operational efficiency and maintaining product integrity.

The Advantages of SOMAS Segmented Ball Valves

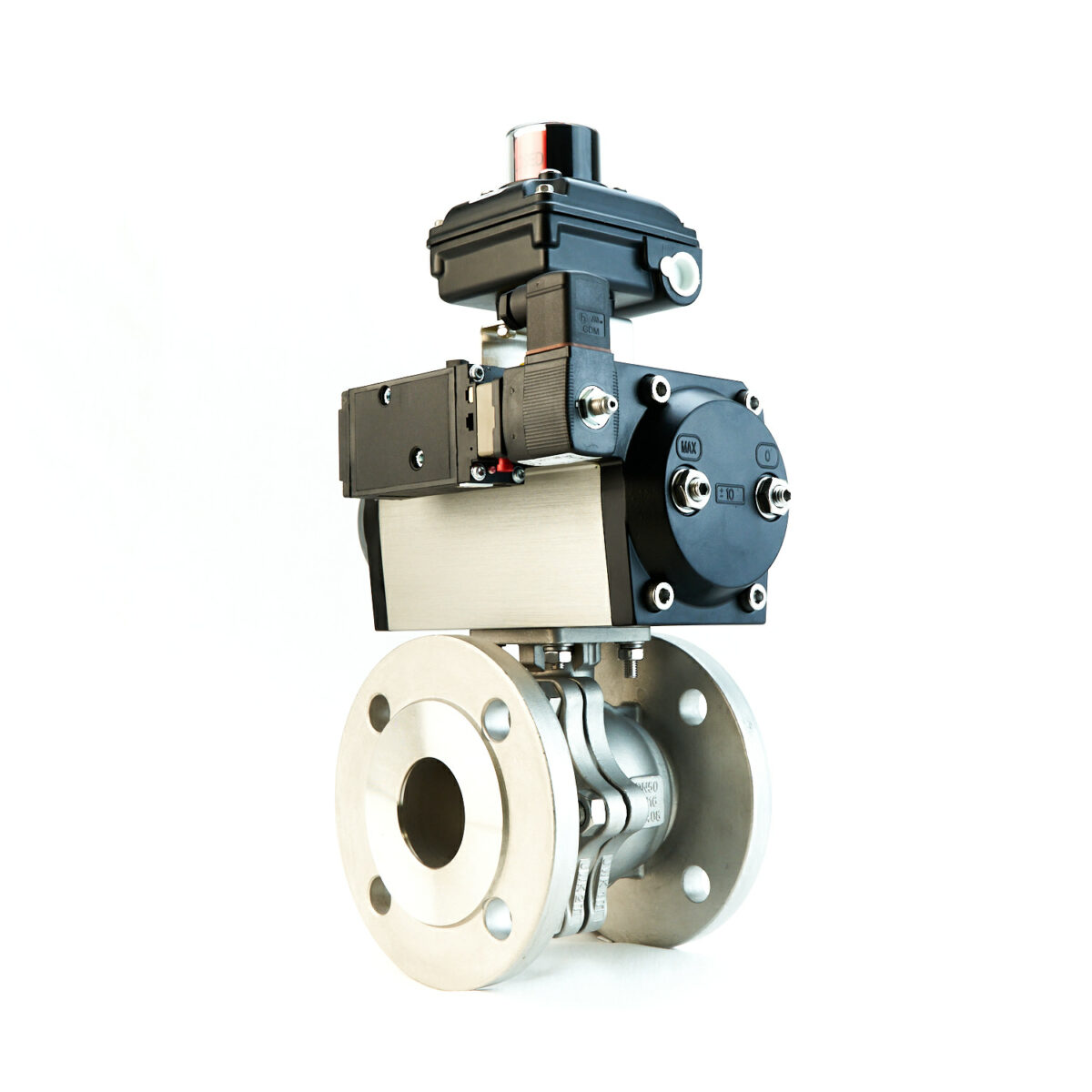

SOMAS is at the forefront of segmented ball valve technology. The Swedish manufacturer’s segmented ball valves are distinguished by their high quality, high capacity, and precision control. This is thanks to their unique seat and ball segment design, which offers operators granular precision and consistent flow rates. This makes them particularly well-suited for the distillery industry, where control over the flow and pressure of liquids is critical to the quality of their products.

Application in the Distillery Industry

The distillery process, with its emphasis on purity and consistency, benefits significantly from the application and operation of segmented ball valves. SOMAS ball segment valves have been utilised effectively across the distillation process, from within steam inlets to the stills themselves. Their ability to provide high-capacity flow control with minimal noise and vibration is highly valued by distillers, as is the precision offered by these valves, which directly impacts the quality of their final product, brands, and reputation.

The Key Benefits and Features of SOMAS Segmented Ball Valves

- Precision Control: The V-notch design of segmented ball valves is a hallmark of their precision control capabilities. This feature allows for a seamless and accurate adjustment of flow, ensuring that your processes are finely tuned to meet specific requirements. The inherent equal percentage flow characteristic of the V-notch facilitates consistent control across a wide range of conditions, making these valves particularly valuable in applications where precision is paramount to achieving optimal outcomes.

- High Capacity: SOMAS ball segment valves are renowned for their high capacity, giving them an advantage over the competition for their flow control. The innovative design of the seat and ball segment allows for greater flow rates through the valve compared to other industrial valves of the same size. This capability ensures that your system operates efficiently, with the ability to handle higher volumes of fluid or gas without compromising on control or performance.

- Durability: Designed to withstand the rigours of any industrial environment, SOMAS segmented ball valves boast a robust, high-quality construction that promises longevity. Their durability translates into reduced maintenance needs and a lower likelihood of downtime, ensuring that your operations run smoothly over time, while also reducing the cost of replacement. This resilience is key to maintaining continuous production and safeguarding against unexpected interruptions.

- Efficiency: The compact and efficient design of SOMAS valves not only contributes to space savings but also to cost reductions. These valves are engineered to perform optimally without requiring extensive space, making them an ideal choice for installations where space is at a premium. Their efficient operation reduces the energy needed for valve actuation too, leading to cost savings in power consumption and allowing for the use of smaller actuators, further optimising your investment.

Enhancing Your Operations with SOMAS Valves

The adoption of SOMAS ball segment valves is transforming operations across the distilling industry, showcasing their role in enhancing process control and increasing efficiency. These valves have been chosen for their unmatched precision, offering distilleries the ability to fine-tune their operations with unparalleled accuracy.

The feedback from the industry underscores the valves’ contribution to quieter, more stable processes, which leads to improved product consistency and quality. By integrating SOMAS valves into their systems, distilleries are experiencing benefits that extend beyond the immediate control of fluids, reducing operational costs and optimising space. The specificity with which these valves can be sized and applied, thanks to advanced sizing software, ensures that each installation is perfectly matched to its intended application. SOMAS segmented ball valves have an established track record of the operational efficiency and reliability of distilling processes.

SOMAS ball segment valves have set a new benchmark in the field, offering a blend of precision, durability, and efficiency unmatched by traditional valves. For the distillery industry, where the consistency and purity of the product are crucial, these valves have proven to be invaluable. Their design ensures not only the meticulous management of fluid dynamics but also contributes to the sustainability of operations through enhanced durability and efficiency.

To find out more about SOMAS segmented ball valves and how they can benefit your business, contact BM Engineering today. Email our team and they will be happy to help you discover how SOMAS ball valves can benefit your business, and become an integral part of your industrial processes.