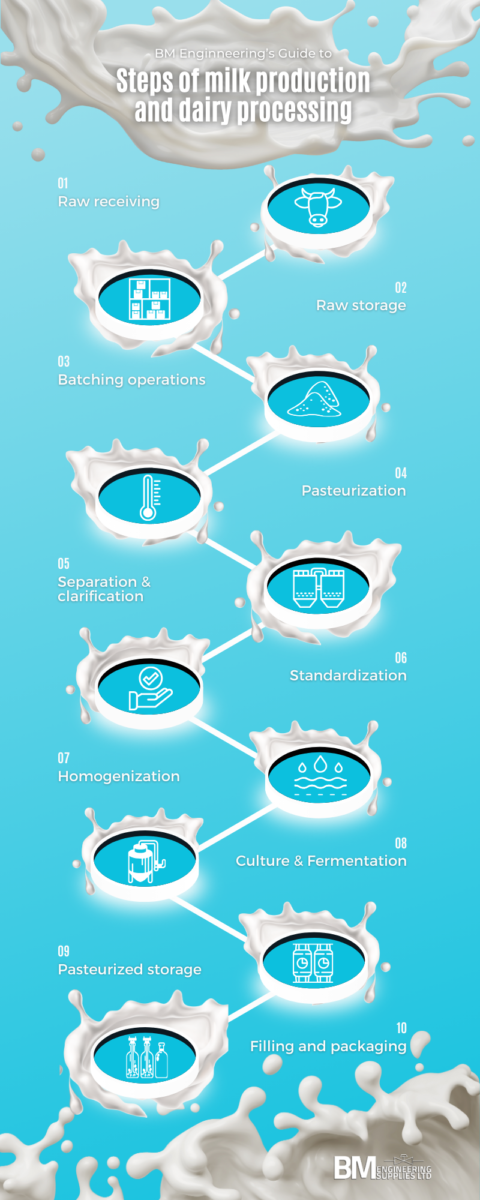

Steps of milk production and dairy processing

The dairy processing process includes the following steps:

The milk/dairy processing includes several key steps to ensure the quality and safety of the final product:

1. Testing raw milk for quality and safety upon arrival before accepting it for further processing.

2. Store untreated raw milk in large tanks and closely monitor temperature and duration to maintain its quality.

3. Combining liquid and dry ingredients in precise ratios to meet the required recipe and batch size.

4. Using heat to eliminate harmful pathogens and enhance the safety of the milk during pasteurization.

5. Separating skim milk from cream using centrifugal forces and using clarifiers to remove any unwanted particles.

6. Adjusting the fat content of the milk to a specified value to ensure consistency and cost-effectiveness during standardization.

7. Breaking down fat globules to prevent the formation of a cream layer during homogenization.

8. Using bacteria cultures to regulate the acidity, consistency, flavour, and aroma of cultured milk products during culture and fermentation.

9. Refrigerating to maintain the safety and quality of milk during storage after pasteurization.

10. Transferring the milk into various types of packages and organizing it for storage and transportation during filling and packaging.

Dairy processing: key considerations for the future

Automation

Automation plays an important role in dairy processing processes by ensuring food safety, equipment safety, and personnel safety while supporting repeatable and robust processes throughout batching, pasteurization, or CIP—a result that’s nearly impossible in manual operations.

Automated equipment monitors tanks and systems to help ensure cleaning, sets off sophisticated alarms to alert if a product is out of the temperature safety zone, and ensures systems aren’t overpressurized or at risk of rupture. This is important for food safety and helps ensure both equipment and personnel safety. New/recent generations of automated dairy processing equipment can even lock out the wrong ingredients.

Automation can occur at the level of a single testing protocol or piece of equipment, or it can span an entire facility, from receiving to packaging. Fully automated facilities may require just two or three operators in a department per shift, who oversee the process from a central control room.

When considering the implementation of automation, a facility’s goal is to achieve a practical level of automation that balances capital costs and operational costs.

The more a dairy processing plant implements automation, the more it can potentially save over time, including:

– Decreased labour costs – Fewer operators mean lower employee costs.

– Improved throughput – The less “human interaction” involved in processing, the fewer shutdowns as a result of an error.

– Proactive maintenance – An automated, data-driven plant is better positioned to predict and prevent equipment performance issues, resulting in fewer unexpected interruptions.

– Product safety – An automated, repeatable process with minimal “human interaction” can improve product quality.

Flexibility

Dairy processing producers are increasingly looking for flexible, multi-product facility designs. This requires the right combination of parallel and concurrent activities to meet flexible processing demands through raw processing; pasteurization; culture and fermentation, as required; pasteurized storage; and filling and packaging.

Dairy processing plant design and construction

One enemy of any dairy plant is unwanted pathogens. Because dairy products are ideal breeding grounds for these unwanted invaders if not handled correctly, engineers must mitigate risk by following hygienic design principles. When it comes to pathogens, prevention is better than cure. Hygienic design principles guide both equipment and material selection and CIP processes to support food safety, as discussed below.

Equipment & material selection

Facility planners must ensure that drains can be emptied when installing all pipes, tanks, and valves. For example, there can be no ledges inside a tank that could prevent it from being fully drainable. Also, careful installation of hygienic valves ensures they function and drain optimally.

When selecting tanks and vessels for use within a dairy plant, facility planners should also consider several other hygienic factors such as avoiding non-cleanable crevices, assessing and selecting agitator blades for their accessibility and cleanability, and ensuring that the location, size, and length of tank top ports enable cleaning.

Selecting appropriate construction materials matters just as much as the overall equipment design. Inappropriate materials in the processing environment allow corrosion and pathogens to evade sanitation activities, putting the product at risk of contamination. For example, the right grade of stainless steel can help prevent chlorinated caustic cleaners from forming pits inside the equipment. Also, elastomers react differently to the fat content, temperatures, and other characteristics of any given product. Selecting the right type of elastomer based on variables in the manufacturing process is key.